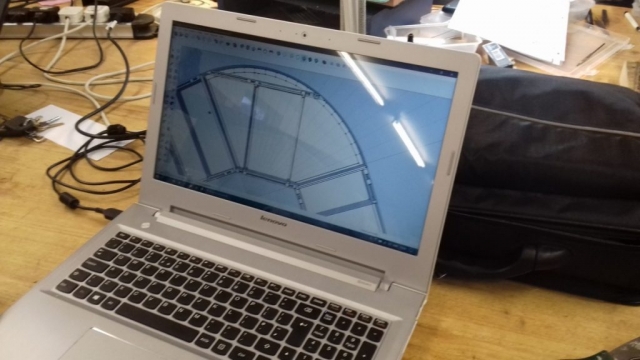

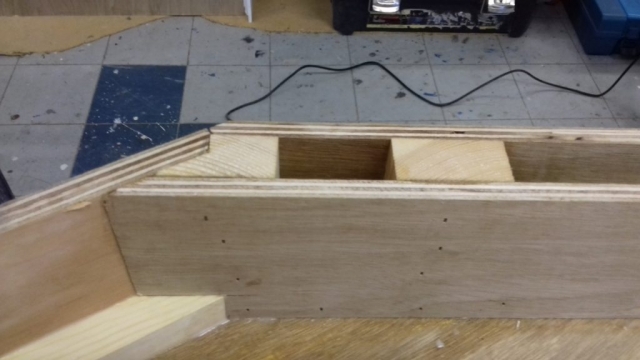

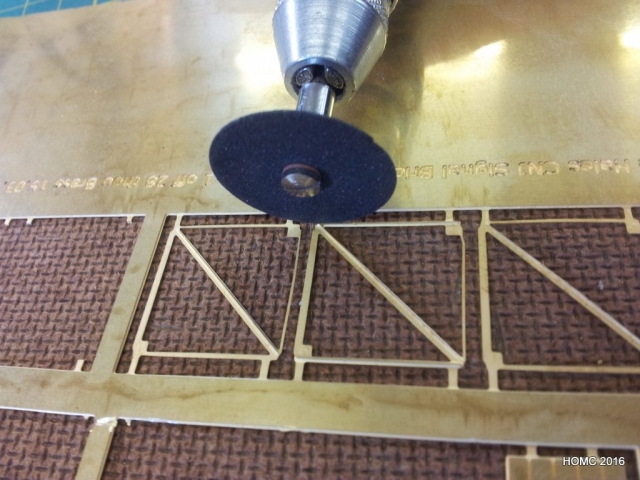

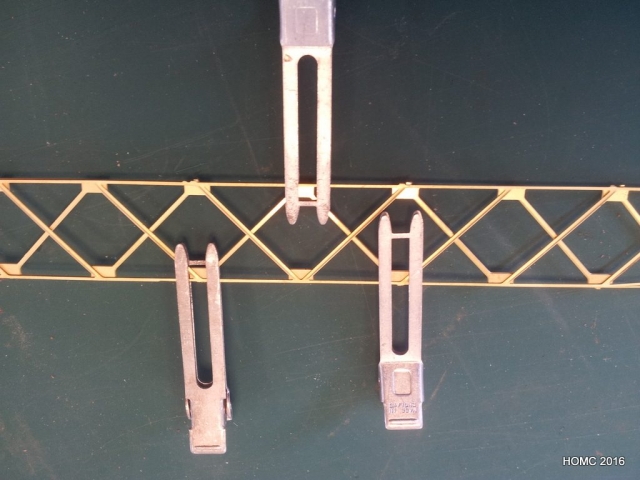

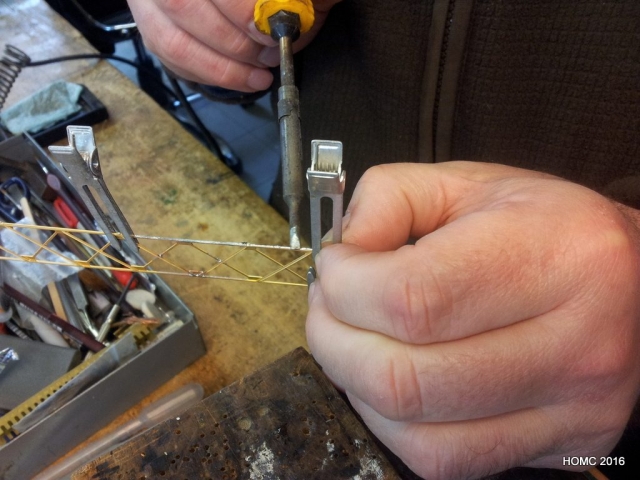

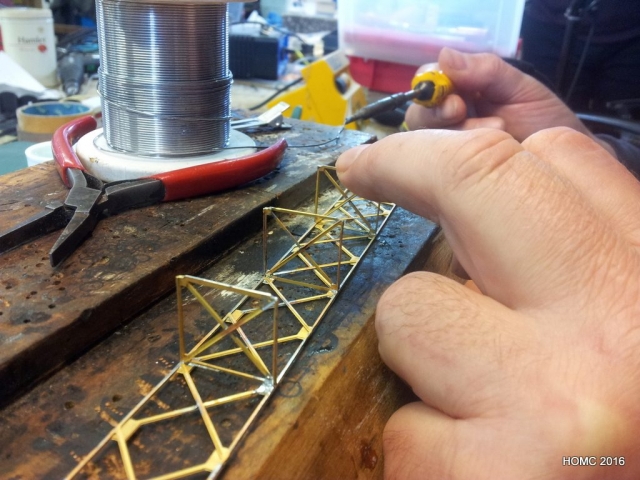

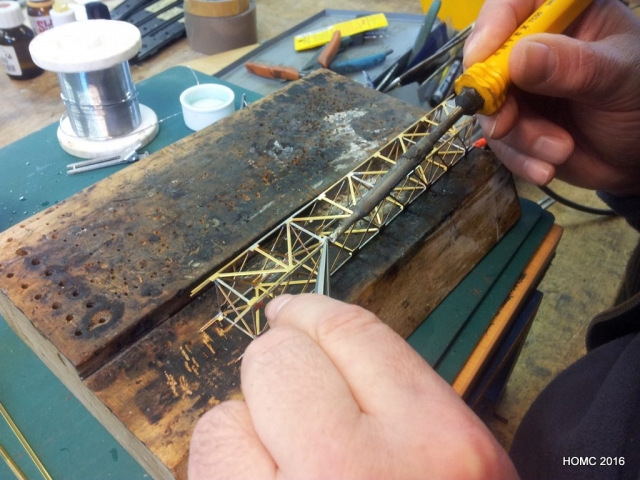

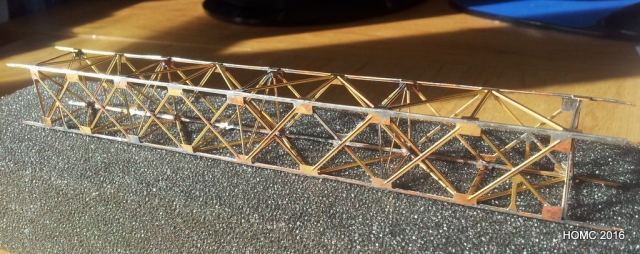

Moving towards Christmas, Gavin again had some free time and used it very productively on the ‘difficult’ corner baseboards with rounded sides. These had already been planned with some very involved angled bracing but with the appropriate tools, these all fell to his skill! Photos show the construction of the two rear corners and then the slightly larger front corner board. Legs were also constructured to fit each.

A good end to the year with lots of work to complete in 2017. Many thanks to Gavin, Richard and the rest of the Barromore team for all their help.