On 16th September, Richard, Dave Faulkner and Steve moved Mauch Chunk back to the rather more spacious Barrowmore clubrooms. From here it is hoped that the layout will again go out to exhibition. We plan to test it and fettle it in November this year in preparation.

Category Archives: Progress

A new home

After a few months in a farm trailer, Mauch Chunk has finally been moved to its new home in my converted garage. Neighbours Pete and Richard helped with the move and the layout fitted into the new rooms almost literally like a glove (as planned of course!).

The photos show the farm trailer, the move (in a Luton van with tail lift), and storage of some parts in a store room and the rest in the new ‘hobby room’.

We have been able to erect two scenic boards that can be worked on. The electrics are all connected and points can be changed with the Big Bear program and trains can be run (a little). The last photo shows my grandson directing me which trains to move where!

Once the storage boxes have been re-organised, scenic repairs and improvements will be started.

The (final?) Big Move

Yesterday – 7th August 2021 – Mauch Chunk was moved from the Barrowmore clubrooms and brought over the Pennines to Yorkshire. This effectively ends five years with the Barrowmore club during which Mauch Chunk has been transformed with a new fiddle yard, mostly new baseboards, new fascias, lighting, wiring, control systems and almost completely new track – all to the highest standard.

It was also been extended to 28ft x 12ft and is now quite formidable! Indeed, it won the the best visitors layout award in Glasgow, the best non-British layout award at Warley and an invitation to retire it to the National Model Railway Museum!

It will be worked on at my home in the East Riding, where my wife and I moved 3 years ago, but it is currently stored in a large trailer on a local farm.

Members of the East Riding Finescale Modellers model railway group are planning to help with further detailing and scenic enhancements as well as maintaining the rolling stock.

Etching, Soldering and woodwork

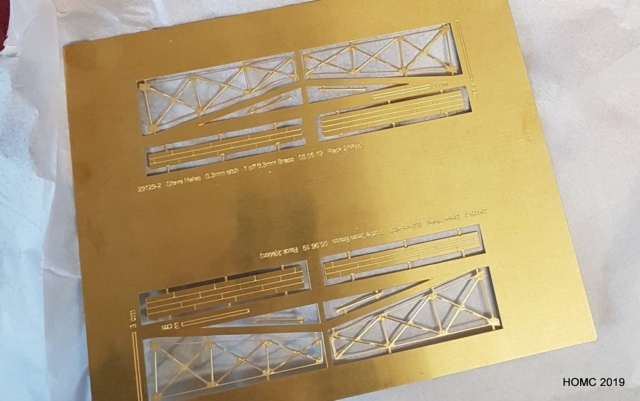

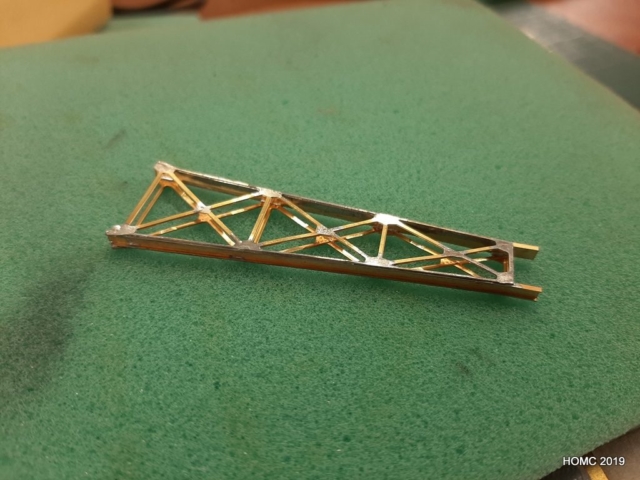

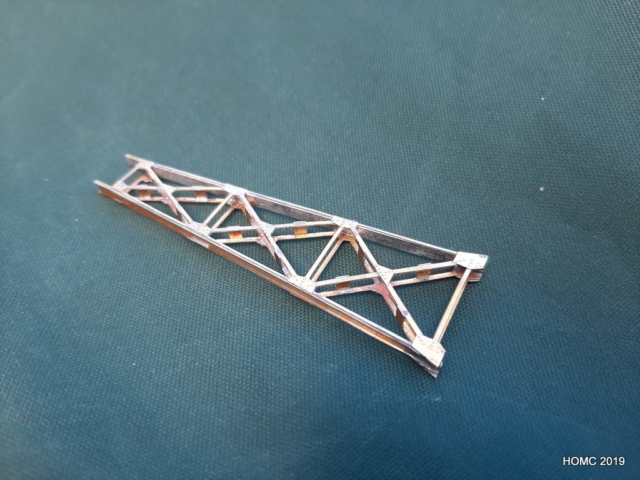

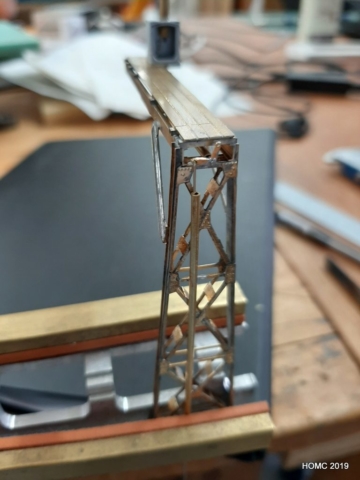

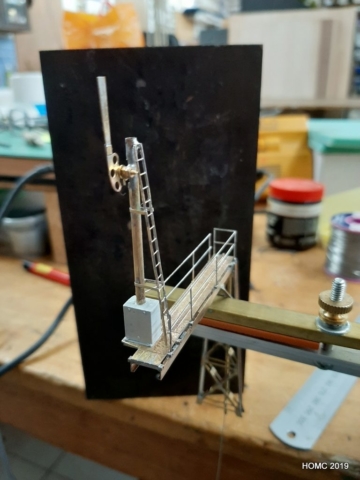

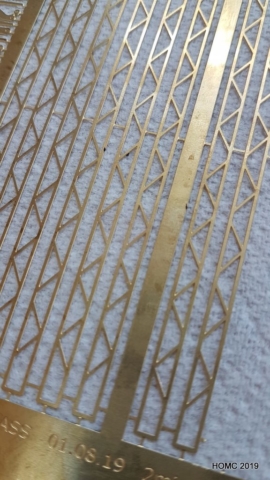

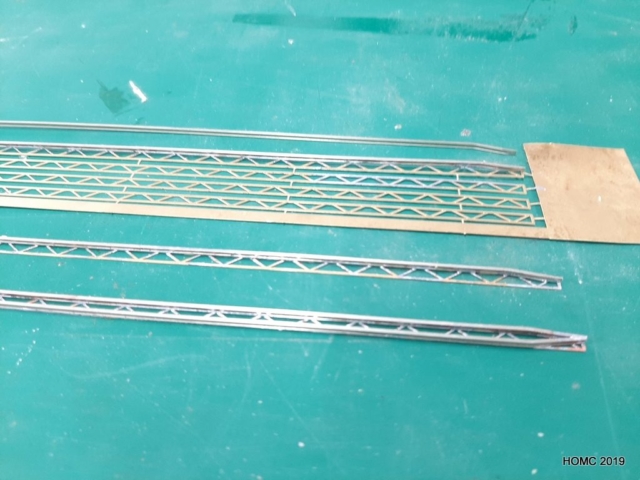

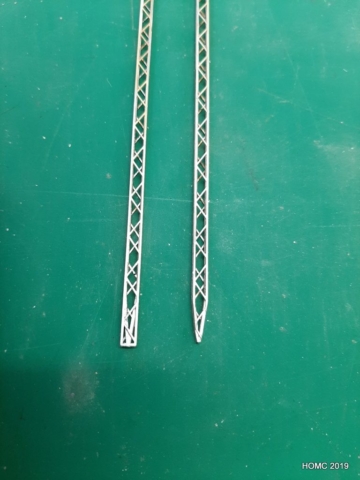

We’ve been doing more etches and soldering to make the signal gantry that stands against the back wall, controlling use of the locomotive servicing track that runs against that wall all the way through to the engine house, refueling facility and turntable.

Photos of this gantry were not clear about all the features so similar gantries were identified in Joel Rosenbaum and Tom Gallo’s pdf book: Jersey Central Lines Official Photography. Steve drew the stanchion artwork and PPD then etched these for us on 0.7mm brass. Richard then used these as the basis for the gantry scratchbuilding most of the other components. Finally the arm was actuated with a servo controlled by Tam Valley Depot’s dual 3-way Servo DCC accessory decoder. This is a new approach for us and means that we can control the signal from software (Big Bear) as well as push buttons. The build is shown here as well as the result

This is our gantry compared with the prototype shot! Prototype photo by kind permission of Morning Sun Books [taken by Charles Houser Sr, The Houser Collection from page 82 of Jersey Central Lines in Color Volume 2 by William J. Brennan].

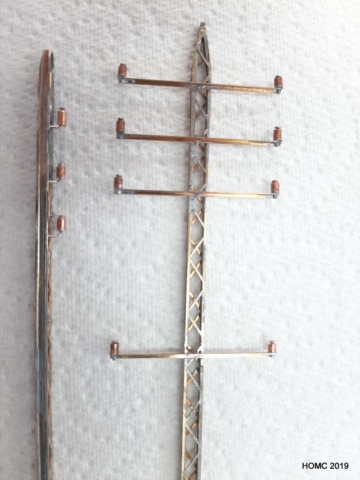

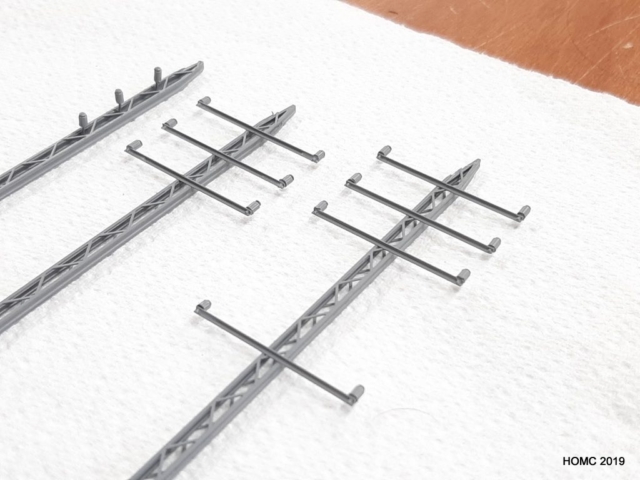

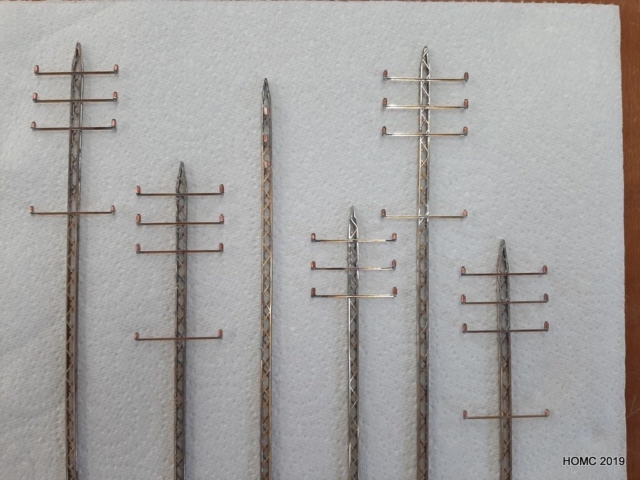

As well as this masterpiece, the hollow framework utility cable posts that can be seen in some prototype photos were drawn up by Steve, etched and then built by Richard using bullhead rail for the sides. Steve then planted them on the layout and modified a few other posts.

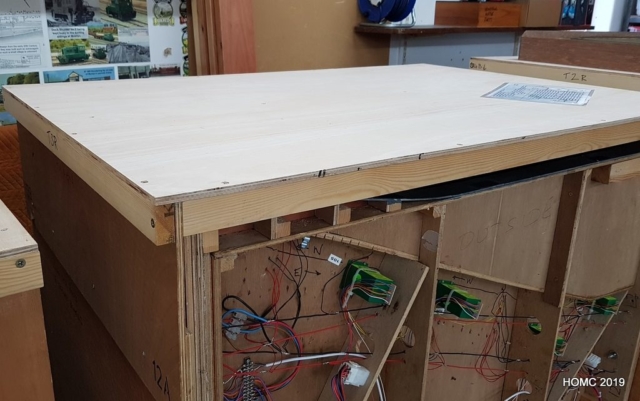

The trolleys get a lot of wear in transporting Mauch Chunk to exhibitions but also in supporting the other Barrowmore layout, Johnstown Road, when Mostyn is erected. We decided to strengthen the trolleys with easily removed ‘lids’ which Gavin built. This has made the trolley boxes much more rigid

More reliable operations – changes

We have started working again on Mauch Chunk since getting back from a succesful exhibition in Glasgow. We had two problems there that impacted on operations, although hopefully the public didn’t see anything substantially wrong.

Firstly we had overheating of the Lenz LZV100 command station. This was partly because I didn’t take the lid completely off the really useful box we’re using for the control panel. However, overheating did occur again later even when the box was completely open. Clearly passive air cooling isn’t enough when we are operating so intensively for 7 – 8h periods.

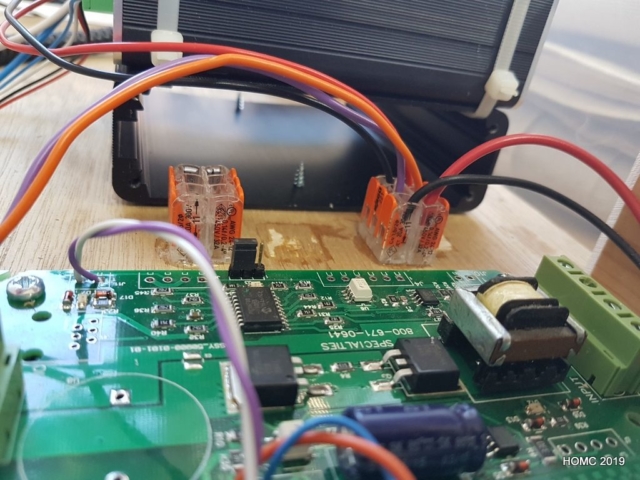

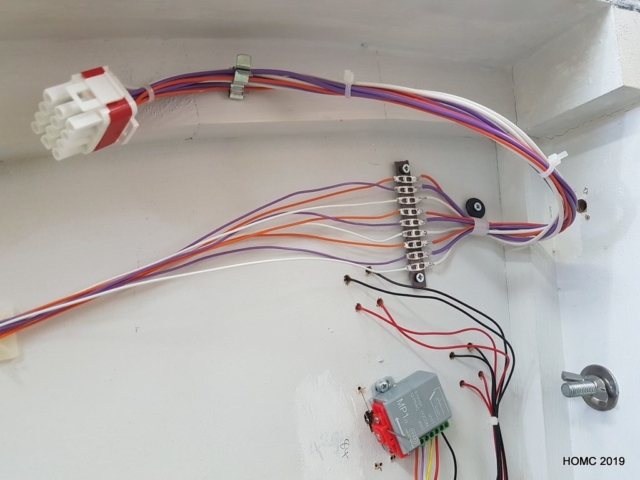

To remedy this, Gavin has put a fan in one end of the box, holes in the other and reorganised the interior to allow a good airflow. The Lenz LZV100 is now also mounted on a hollow support to allow airflow beneath as well. It should work nicely and will allow us to leave the lid on next time!

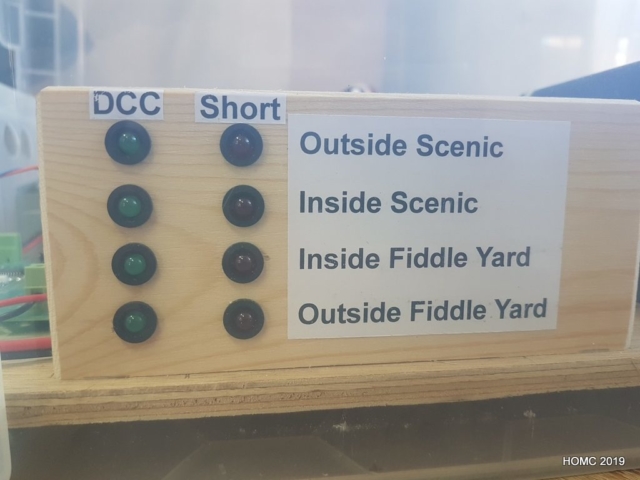

To put the icing on the cake he (and Dave Faulkner) have also wired the block protector boards to LEDs that display when a short is occuring – this will make it much quicker to detect problems.

Secondly, we had problems with the Peco point motors (in the staging yard) misbehaving. This is likely to be due to poory alignment/positioning which has occured as a result of heavy use and the way that they operate – with a thud in each direction.

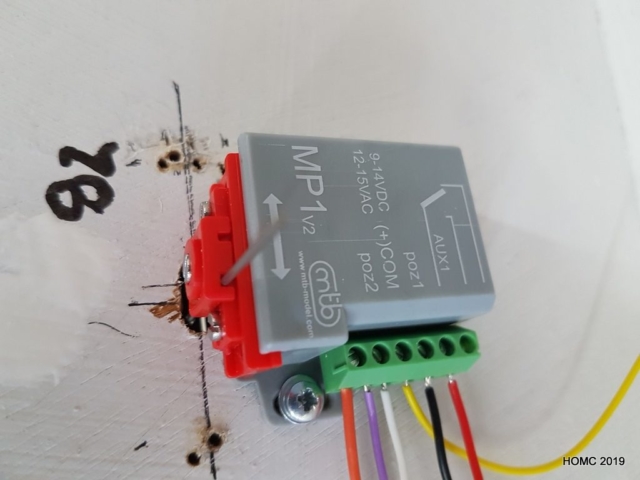

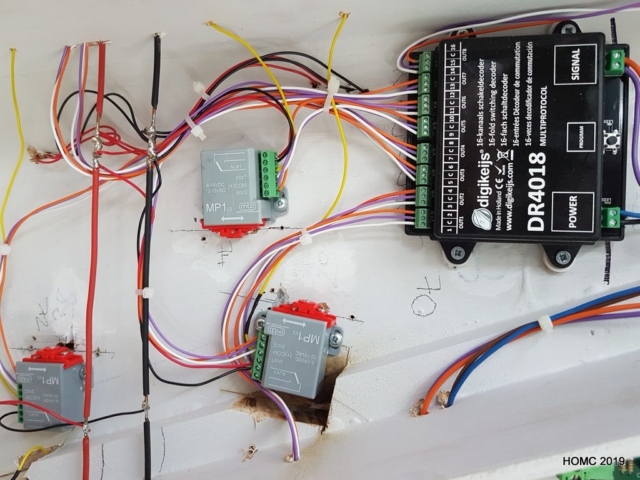

We decided to try a servo design which has a more genteel motion. As there was not enough vertical space for Tortoise motors, have gone for MP-1 point motors from MTB Model (click here) in Prague. These are supplied by DCC Train Automation in the UK (click here). To control these with DCC we also purchased Digikeijs DR4018 accessory decoders, also from DCC Train Automation (click here) which each control eight motors.

We had to include some cross-baseboard links for control to avoid wasting the channels on the accessory decoders. Although it is a pain to replace and rewire all the motors in the yard, provisionally it looks as though it will be a good investment. We will report here on our experiences.

Prepared for Glasgow

We’re all prepared for Glasgow!

Last week we set out all the stock and tested it in new consists and configurations. Everything (well nearly…) ran well and since then several items have been further weathered. Richard’s new K1s 4-8-0 has been completed and is running and photos also show an ABBA F3 set hauling a long freight Westbound. Other photos show the locomotive and other stock lined up in their fiddle yard roads.

Finally, the new fascia lettering is coming together!

We hope to see some of you at the Scottish Exhibition Centre on Friday through Sunday this weekend.

Preparing for Glasgow – part 2

Work is still progressing on preparations for Glasgow – most of it in intensive sessions coinciding with Steve’s visits to Barrowmore from East Yorkshire.

Photos show Steve weathering boxcars with Pan Pastels, these were then sprayed with fixative and/or acrylic matt varnish. The spraying does fade some of the colours, particularly the brown and organge, but has the advantage of fixing them.

Richard continued making corridor connections for all the passenger cars from black card, scored and folded into concertinas then superglued to the car ends. A LOT cheaper than the commercial options and looks just as good.

Dave (Millwood) continued to help by ballasting the gap in the platform and making more of the cantilevered telegraph poles for the extended LH end wall. Steve also made and planted many more telegraph poles for the RH end and the front.

Richard replaced the broken plastic handrails (they are so fine) with brass wire equivalents on half a dozen small tank cars – a substantial task. Gavin airbrushed the latest K1as camelback prior to decaling.

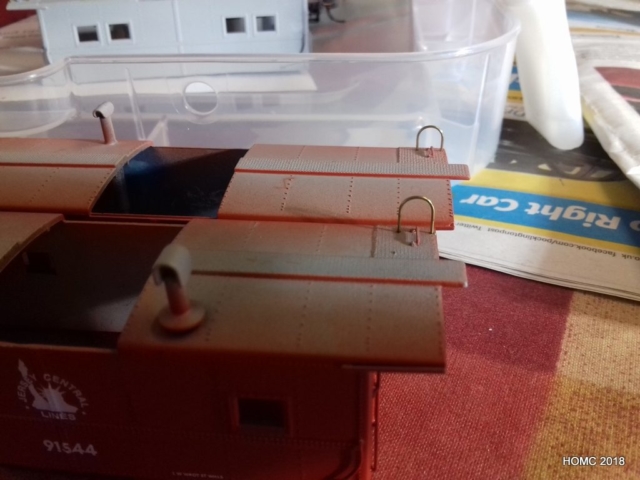

Finally the stock was set out to arrange train consists prior to reboxing it in the correct order. Note the new caboose tail ligthts.

Preparing for Glasgow – part 1

Another trip to Barrowmore in early December resulted in more progress: Firstly we had to rescue Mauch Chunk from underneath a substantial pile of baseboards – mostly associated with the O-guage Johnstown Road layout. The Barromore clubrooms only have room for one of our large layouts to be erected at a time and the others usually need to be moved round each time to accomodate this. Gavin and Richard helped erect Mauch Chunk and all was well once a connector had been partly rewired and a mysterious short had been eliminated.

Richard got down to building (soldering) the remaining fencing for the roadway on the RH side of the layout – there hadn’t been enough uprights in the original etch – and I (Steve) got on with spray painting them and drilling holes for all the uprights. Eventually Richard soldered the pieces together in situ and after a final handpaint of these parts they were done.

Dave Millwood – an S4 modeller who is new to Mauch Chunk – is rebuilding the other fencing between the roadways and track which on reflection we had decided was overscale.

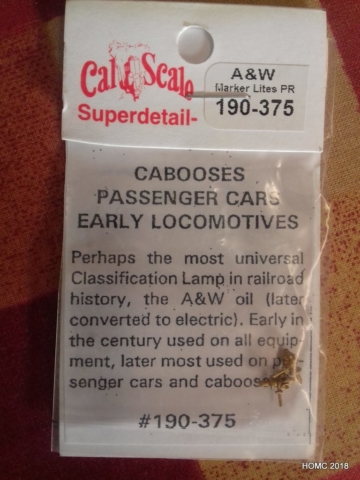

I have also been preparing 24 sets of Cal-Scale Marker Lites (PR 190-375) to use on the cabooses. After removing the sprue and filing smooth, they were painted yellow. Three of the lamp sockets were painted yellow and one red as per the prototype. These were then filled with Glue’n’Glaze crystal clear (From Deluxe Maaterials) in two stages with overnight drying in between – which produced realistically shaped lenzes of the appropriate colour. Finally holes were drilled and these were fitted to the cabooses.

After all this activity, Richard and I relaxed by trying out some switching moves using a mixture of fixed undertrack magnets and the big hand in the sky. This latter will hopefully be at least partially replaced with Subarishi smart-couplers before Glasgow in late February.

Kitchen table modelling

The visit to Barrowmore with the caravan took place and the camelbacks and the H1 were decalled with liberty heralds. Unfortunately painting with a matt varnish resulted in white deposits which will need to be disappeared during weathering. Decalling some of the next phase of cabooses (another half dozen) was more succesful.

I also attempted to start building the post office, but a long time having elapsed since my last buildings were constructed (ten years?!?) resulted in a degree of incompetence that made me yearn for something more reliable. I have therefor embarked on planning to get at least the framework cut with a laser cutter. Should this prove succesful it could result in the purchase of a laser cutter by Barrowmore MRG at some point in the future.

Locally I have been attending the East Riding Finescale Modellers group in Hull. A fine bunch of fellows who seem to manage to model to a high standard by the expedient of standing round chatting and drinking tea – I expect to be enlightened some time soon!

Most recently I resorted to the kitchen table to finish decalling the latest cabooses (modified from generic NE cabooses), adding roof grab irons and painting their roofs. Just the tail lamps to add to a selection and they’re ready for Model Rail Scotland in February.

Summer hiatus broken by Gavin!

Since the last post I (Steve) have moved house to the East Riding of Yorkshire and this has somewhat impacted my modelling opportunities. The layout was taken down in early July and will probably not be put up again until December to allow modelling on the boards prior to exhibiting at Model Rail Scotland.

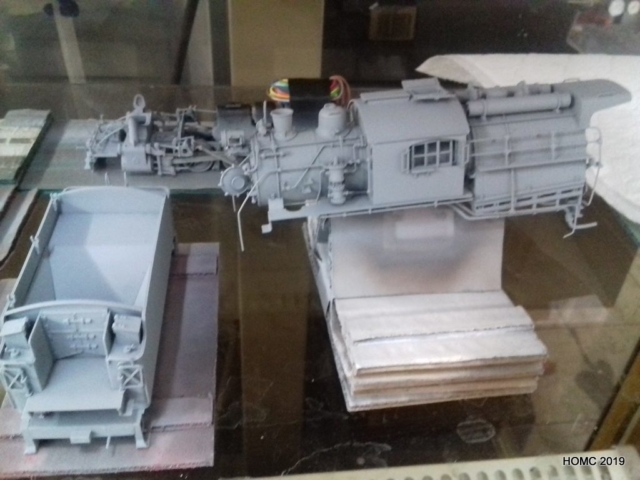

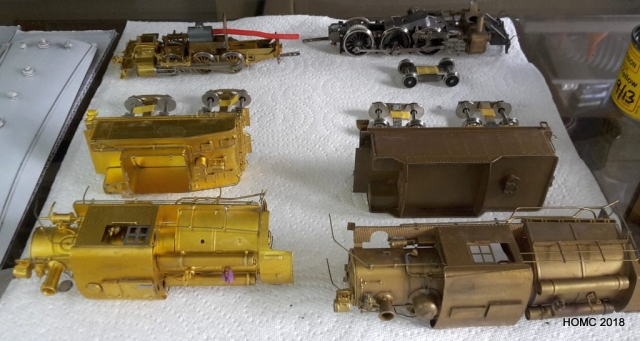

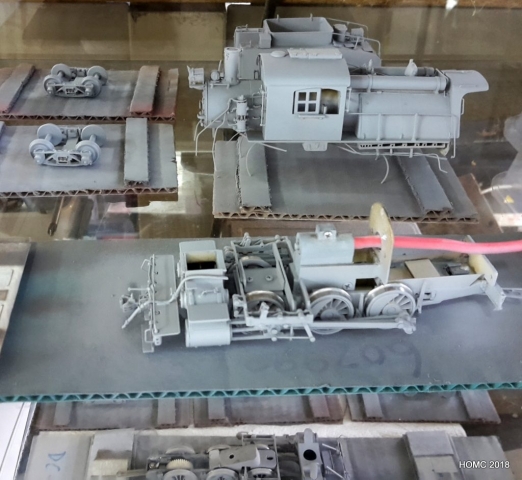

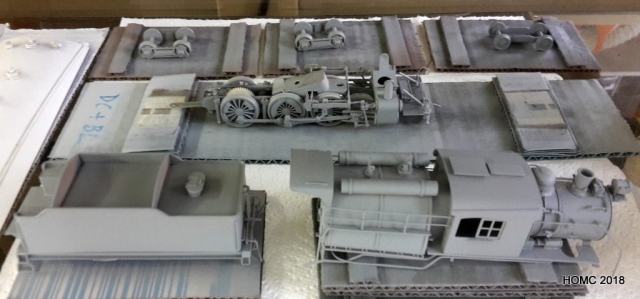

However, there is no holding Gavin back: He has worked on the motors and DCC chips of two of my camelbacks still in the original brass – a 4-6-0 L by Red Ball and an 0-6-0 B4 by Overland Models. These still need decaling and weathering which I will do on a visit back to the Barrowmore clubrooms hopefully in September (taking our new, well 2004, caravan!).

The 4-6-0 will supplement our existing 4-6-0 on (mainly teminating) passenger train duties. The 0-6-0 was not a regular visitor to Mauch Chunk, but will be used for switching around the goods shed and in the coal sidings at the Western end.

In the meanwhile, enjoy these photos – also seen on the BRMG facebook page.