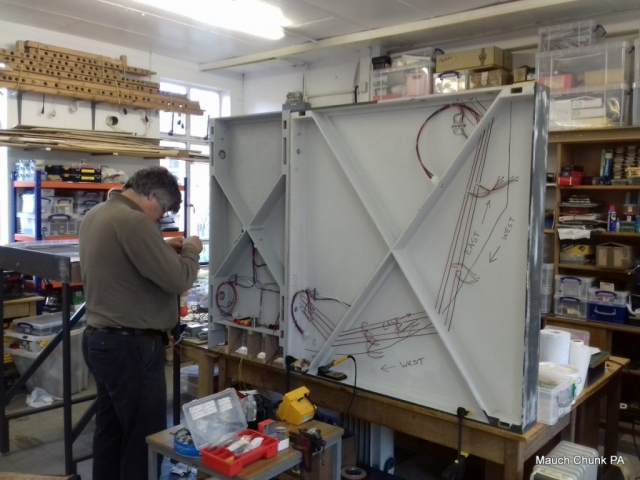

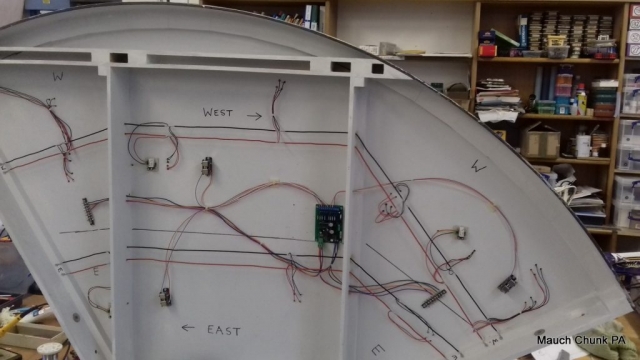

Leading up to the Barrowmore Open Day, Gavin built us some elegant and practical lighting gantries. These were based on the idea previously used on the ‘ladder-based’ gantry used for phase 2 of Mauch Chunk but Gavin has developed it to a point of brilliance.

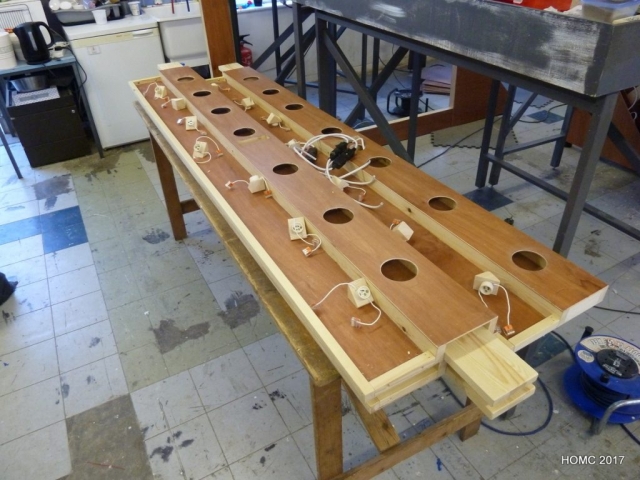

The main factor in this was the use of spot bulbs mounted in ‘naked’ GU10 lampholders. This time we have used mains power, 5W, 420 lumen LED spotlights with 120 degree coverage. We used Wago 3-position connectors for each bulb to keep the mains power safe and connected beams with ‘kettle’ type connectors.

Gavin built ‘Bennet’ style gantries modified to have extra long arms and legs to go over the wide scenic boards of Mauch Chunk. The beams were also modified by extending the front edge down to use as the fascia. The arms hold the fascia about 6 inches forward of the baseboard front and ensure that the whole of the scenic area is illuminated.

Large holes were drilled in the back face of the beams every foot to hold the LED bulbs and these were angled at about 45 degrees by mounting on triangular cross section wood. LED bulbs do not get hot so there is no heating of the wood.

When the bulbs are removed, the beams can be stored together for transit.

It all works brilliantly!